China Design Angle Stop Valve Cork For Sale Maker Company

Stop valves are indispensable in the realm of fluid control, offering a straightforward yet effective means of managing the flow of liquids and gases.

Stop valves are essential components in fluid control systems, designed to interrupt the flow of liquids or gases. They are commonly used in plumbing, industrial processes, and heating systems. These valves are manually operated and can be either on-off or modulated, allowing for precise control. Stop valves are available in various materials to suit different fluid types and pressures, ensuring reliability and durability in diverse applications.

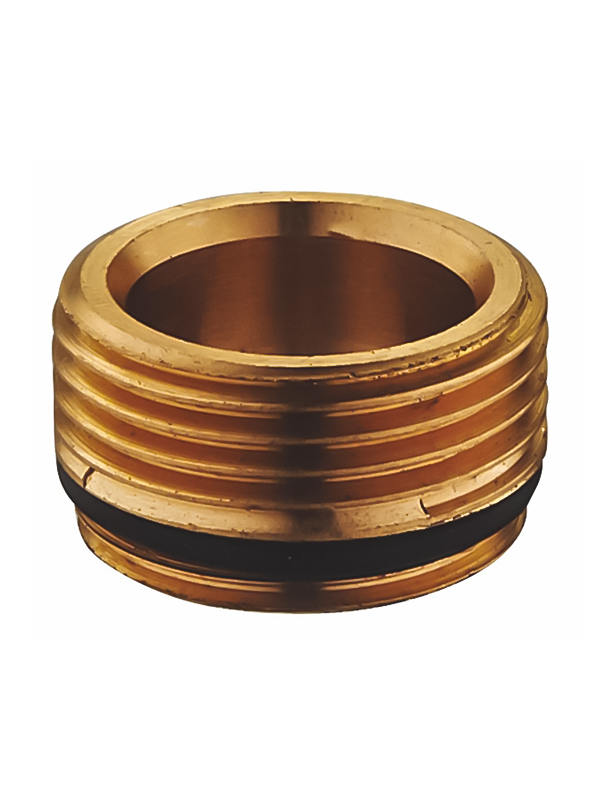

Stop valves are characterized by their simple yet robust design, which typically includes a movable closure member, known as a plug or disc, that is used to open or close the valve. The plug is usually round or tapered and is guided by a cage or a stem to ensure smooth operation. The valve body, through which the fluid flows, is often designed with a straight passage to small resistance and ensure laminar flow.

There are several types of stop valves, each suited to different applications:

Globe Stop Valves: These are the more common type, featuring a circular plug and a relatively low flow resistance.

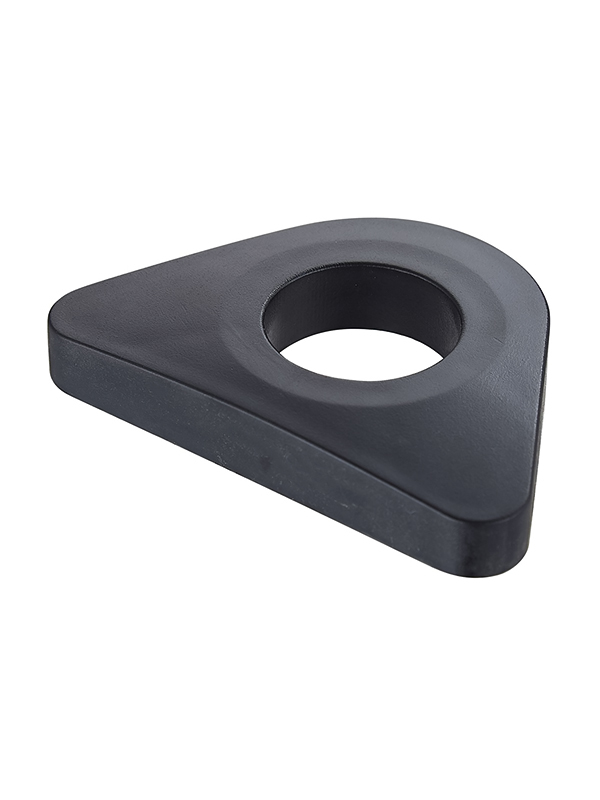

Angle Stop Valves: As the name suggests, these valves are installed at an angle, which can be beneficial for certain pipe configurations.

Gate Valves: These are similar to stop valves but are often used for larger diameters and higher pressures.

Ball Valves: These use a spherical closure member that rotates to control the flow, offering a quick operation and a tight seal.

Stop valves are used in a variety of applications due to their ability to provide a tight shut-off:

Water and Wastewater Treatment: They are used to control the flow of water in treatment plants, ensuring efficient operation and preventing backflow.

Oil and Gas Industry: In pipelines, stop valves are crucial for controlling the flow of oil and gas, as well as for safety shut-offs in case of emergencies.

Chemical Processing: These valves are used to control the flow of chemicals, ensuring that processes are carried out under controlled conditions.

Power Generation: In power plants, stop valves are used to control the flow of steam and other fluids, which are essential for the generation of electricity.

HVAC Systems: In heating, ventilation, and air conditioning systems, stop valves help regulate the flow of water or other fluids to maintain comfortable conditions.

The use of stop valves offers several advantages:

Control: They provide precise control over the flow of fluids, which is essential in many industrial processes.

Durability: Stop valves are built to withstand high pressures and temperatures, making them suitable for a wide range of applications.

Maintenance: Due to their simple design, stop valves are relatively easy to maintain and repair.

Safety: They are often used in safety-critical applications where a reliable shut-off is necessary to prevent accidents.

Despite their many benefits, stop valves can face challenges such as wear and tear, which can leaks or failure. Regular maintenance, including periodic inspections and replacements of seals, is crucial to ensure their longevity and reliability.

Stop valves are a fundamental part of fluid control systems in modern industries. Their ability to provide a secure shut-off and control flow makes them an essential component in a variety of applications.